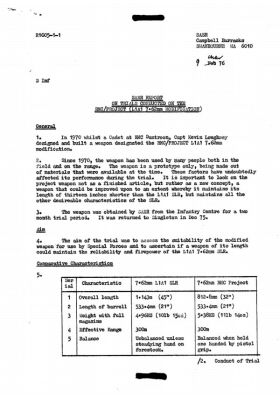

General Purpose Infantry Rifle

Fig 1. The RMC No2 made at SAF under Scientific Advisor 1971.

The KAL1 made at 3 Base Wksp Bn by Loughrey & Witt 1973-74

The AusSteyr F88 selected by ADF to replace L1A1 1985.

The Dragunov-SVU-A 7.62mm Sniper Rifle 1994

With Noise Suppressor, AK-47 action & Auto-Fire Feature.

Fig 2. 1967 - Kevin Loughrey (15yrs old) with Gecado 25 about to

embark on a 7 day solo canoe trip down the Brisbane River

Fig 3. Nov 1969 - Staff Cadet Kevin Loughrey with L1A1 Rifle

RMC Annual Field Exercise Brindabella Mountains

Photo by Staff Cadet Warwick Elliott

Fig 4. Nov 1974 - 3 Base Wksp LT Kevin Loughrey &

CFN Andrew Witt Fitter&Turner Asst

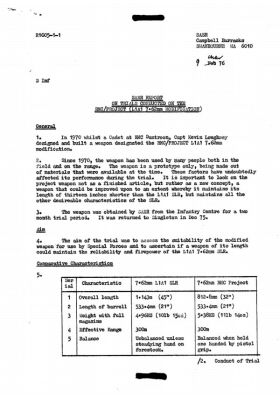

Fig 5. Comparing the RMC No2 and KAL1 to the L1A1

(Top to Bottom) L1A1, RMC No2(Apr 1970), KAL1(Sep 1973)

Fig 6. KAL1 Field Stripped shortly after firing

Note only three large pieces to clean.

Fig 7. Extremely stable and accurate "basic" prone position

with two hands on the pistol grip, firing left handed.

Fig 8. Extremely stable and accurate "basic" prone position

with two hands on the pistol grip and Sniper Scope fitted.

Foreword

I have written this page in a personal manner for a number of reasons. This page is for my friends and those who have encouraged me over the years; believing in the value of the ideas I was pursuing with respect to an ideal general purpose infantry rifle. It is also to fully document what happened with this invention and to illustrate how difficult it is to have new ideas accepted; particularly in the Australian Defence Force. It seems to be something cultural, dating back to the early days of settlement where the best crockery or furniture always came from the "old country" and one gained one's social status, not by using the local product, but by showing off imported acquisitions. I have also been amazed at how many web-sites have posted information about the KAL1

GPIR (including Wikipedia!) and so I thought this audience would like to hear the full story. As much as I can, without harming the reputations of some people, or betraying confidences, I have provided copies of original correspondence.

At the end of this "journey", there were two rifles. Both of them working. The one at the top, RMC No2, had fired over 20,000 rounds; the KAL-1, a couple of hundred before the project was closed at the direction of Army Headquarters as a result of pressure brought to bear by Army Design Establishment. Both rifles were in working condition when they were handed over to the Infantry Centre. With comparatively little engineering effort, the KAL-1 could have been transformed into a polished operational weapon of any desired calibre. It was a great opportunity lost to the Australian Defence Force because of a profound lack of leadership and imagination on the part of some very senior officers.

Background

I have always from childhood been an inventor. I had three older brothers, John, Blair and Peter and we spent a great deal of our time in the bush surrounding the village of Dinmore around 20 miles West of Brisbane. By the time I was 15 years of age, I had 5 rifles. Two air-rifles, a Gecado 25 and a Gecado 50 target rifle, I bought from the money I earned doing paper rounds in the morning and evening for my father who owned the local grocery store, Newsagency and Post Office. I also had two .22 rifles, one of which was a semi-automatic and one bolt action. The semi-automatic was actually my brother John's and so was the .303/25 that he entrusted to my care when he couldn't take it with him wherever he was living at the time. My brothers were all highly inventive.

We did the usual "Huckleberry Finn" things like make rafts, model aeroplanes, crystal (radio) sets, cracker guns, bombs, bridges and so on. All three of my brothers, went on to science based educations and professions. John gained a number of degrees the last being in Medicine and Surgery. Blair gained a degree in Industrial Chemistry whilst Peter became a civil engineer and has worked on many of the largest engineering projects in the world; including Australia's Parliament House.

This rifle (or rifles as it turned out to be) is not really as much an invention but the amalgamation of the ideas of others.

It was built from L1A1 parts only as a matter of expedience. As to the final calibre, I figured that would be a matter of policy, largely determined by Australia's need to have interoperability with its Allies; primarily the US. The design of modern small arms can be traced back to the 1800's. If there have been substantial advances in more recent times, they mainly apply to things like materials, propellants and sights. Locking mechanisms come in many forms but essentially, they all perform a similar role. When unlocking, some of the more refined designs have a primary extraction stage, to loosen the stiction of the cartridge

against the chamber wall, and then the rude extraction to fully remove the cartridge; this two stage process helping to reduce the instances of separated cartridge cases and allowing the walls of cartridges to be made thinner and hence lighter. I made two rifles against a significant amount of entrenched resistance and, at times, risked my career in doing so. I would really like before I finish my engineering days and hang up my vernier to make the final model; built the way I think a rifle should be. What would that consist of:

- Most probably a bull-pup butt design so as to have the shortest, lightest possible rifle with the longest possible barrel.

- Ambidextrous operation by having:

- the cocking handle on the top

- the safety catch in front of the trigger (bringing other benefits besides that of ambidexterity)

- large magazine catch that is equally accessible from both sides of the weapon and uses the strong gripping action of the hand to release it as the magazine is simultaneously pulled downwards

- easy adjustment of sights from both sides of the weapon

- ejection of the round downwards or to the left and right by:

- having a moveable stationary ejector linked to the slide cover, or (and most probably the best and simplest solution)

- having a cowling on the slide cover that simply deflected the round downwards and protected the firer's face from any detritus being blown out of the breech by residual pressure when the bolt retracts.

- Large parts and few of them such that stripping and cleaning the weapon is quick and easy and the parts are hard to lose in poor light or chaotic, difficult surroundings.

- A simple, crude, self cleaning, hard-to-jam, locking action, say, like the AK-47.

- A single return spring that also returned the piston.

- A design which, to the most practical extent possible, utilised common components across a range of weapons.

- An integrated noise suppressor so that firer's did not harm their hearing when operating the weapon without ear protection.(See Silencer Project)

- An adjustable stock length with built in shock absorber so as to provide maximum comfort to firer's with differing anthropometrics.

- An extensible pistol grip so as to assist the use of the basic prone position (see Figures 7&8).

- A smooth exterior to ensure the weapon is comfortable to carry and operate and will not snag on clothing or surroundings.

- Picatinny rails on the top and the bottom of the barrel so that a variety of devices (such as night vision sights, torches and grenade launcher) can be fitted as required.

- Optical and open battle sights.

- A round that was hard hitting and accurate against lightly armoured personnel out to 500 metres with the ammunition being common across a variety of weapons.

- And finally, mechanicals that are easy to fabricate such that the weapon can be mass produced at low cost should there be a national emergency requiring that.

I'm far from being the first person to have experienced resistance from an entrenched and unimaginative bureaucracy when trying to get a new type of small arm accepted by the Australian Army. Evelyn Owen experienced the same problems with his Owen Gun. See "The Owen Gun Chronological Bibliography and Catalogue of Memorabilia and Published Documents" by Alan Stein dated 28 October 2008. (

the following year when he attempted to interest the military, Owen was rebuffed, being told that neither the Australian or British armies had any need for such a weapon.")

In the following,

I have included scans of original letters. In pursuing this idea, my first really big idea, I met all sorts of people. Some were devoid of ideas, delighting in obstructionism, others were helpful just because they knew it was the right thing to do and others gave me the benefit of their skill, imagination and intellect with no expectation of reward. It's been an education. I now appreciate why, in every major conflict, Australians have gone into battle with second-rate equipment led by decent, brave officers, often lacking in science and materiel ingenuity; the one most prominent exception to this probably being Sir John Monash.

The Beginning - RMC Duntroon

In 1969, I gained entrance into the Royal Military College Duntroon and commenced a degree in Mechanical Engineering. At the end of each year a field exercise was held. This consisted of 4 solid weeks of Infantry Minor Tactics with the "Corps of Staff Cadets" participating as a Battalion in a make-believe Divisional exercise. In 1969, the exercise was held in the Brindabella Mountains, its theme being Counter Revolutionary Warfare; influenced by the fact that Australia was, at that time, heavily engaged in operations in Vietnam. During that exercise it rained, then hailed, then sleeted and finally it snowed; all the time whilst we chased "enemy" in black pyjamas pretending to be Viet Cong! I spent my time, when sitting in foxholes, freezing and waiting for the "enemy"

to attack, distracting myself from my miserable state by thinking of ways by which the standard issue rifle, then a 7.62mm L1A1, could be adapted to be a better weapon for the infantry. There were quite a few things wrong with the L1A1.

- It was too long to use in close bushland and jungle.

- The rifle could not be easily operated by people who were naturally left-handed and, even if right-handed, to shoot around the left side of a corner, right handed, in urban warfare requires that the firer totally expose themselves if they wish to take an aimed shot.

- It was heavy and uncomfortable to carry with a tendency for people, when patrolling for a long of time, to let the weapon "droop" towards the ground; thereby making it slower to bring to the ready in a contact.

- The foresight of the weapon was separated from the rear sight by a flexible joint which significantly affected its ability,once zeroed, to maintain its point of aim and hence its accuracy.

- The weapon was primarily black and so stood out against a light green uniform, particularly in grassland, making it easy to spot armed troops.

- When cleaning the weapon, it was possible to jam cleaning cloth in the gas tube and this effectively put the weapon out of action until an armourer could be summoned to remove the blockage or replace the tube.

- Some of the parts of the weapon, when it was disassembled for cleaning, were easy to lose, especially if cleaning was done in poor light or on the leafy floor of a forest.

After exercises were finished I drew up plans and tried to interest the Engineering staff at the University laboratories in my ideas. In June of 1970, I finally wrote a very untidy and poorly worded minute to my Commanding Officer, LtCol Stewart asking that I be allowed to take L1A1 rifle parts and construct a working model of the rifle. To my amazement, my Company Commander was directed to pass me to Captain John Scully, the OC of the workshops at Duntroon. John Scully passed my plans to a Citizen Military Forces(CMF) Officer, Capt John Sankey. His opinion was aimed at discouraging me from further attempts to proceed with this idea and so his

written opinion was fairly negative.

(For details see Sankey's Report)

In my life, I have learnt there are two ways of building things. One is to specify in great detail a set of requirements, draw detailed plans and then build that which you have specified. Invariably, those that follow this path on anything but a routine project, such as building a standard bridge on a main road, will find themselves with something they didn't actually want or that they had overlooked, in the process of the specification, some crucial point. The other is to treat the idea like a piece of clay and mould it, listen to the views of users and continue to change your ideas until you have something that is the best that can be. As can be seen from Sankey's report, he was definitely in the camp of specifying everything to the finest detail. On the other hand,

it may have simply been a ploy, believing that if he made onerous demands I would lose interest and look for something easier to do. Scully's comment of, "It is recommended Staff Cadet Loughrey direct his energies towards a more profitable project.", encapsulates this view.

This rejection had exactly the opposite effect.

The Scientific Advisor, et al

One evening in 1971 (my third year at RMC), while running back to the barracks from sport, a classmate of mine, Rick Davies, enquired about the progress of "the rifle". I told him about the Scully/Sankey report and he said he might be able to help. His girlfriend at the time was the secretary to Mr Max Nesbitt, the Scientific Advisor to the Army and he thought he could obtain for me an interview. I was sceptical but said I would welcome the opportunity. True to his word, Rick organised a meeting. At that meeting I was told, there had been numerous complaints from the Infantry about the unsuitability of the L1A1 Rifle for use in Viet Nam because of its weight, inherent inaccuracy through having a flexing hinge between the fore and rear sights and its long length

which made it unsuitable for use in thick vegetation or close quarter combat. Consideration had been given to copying the AK-47, but for political reasons, this was not thought to be a good idea. The idea of building a better, shorter rifle therefore had some appeal. Max Nesbitt was an amazing and kind person and he had lots of useful contacts; one of which was Mr Eric Duve of the Department of Supply. In those days the Dept of Supply owned and operated the Small Arms Factory at Lithgow. I was introduced to Mr Peter Gardiner and his team who worked from offices in Canberra. Great people to work with. Highly creative, open to ideas and very helpful. I met with these people on

25th of June 1971. From that meeting came agreement to draw up plans for RMC No2; RMC No1 being the original plans for a rifle with a locking action and return spring arrangement modelled on the AK-47. The Dept of Supply team (rightly) concluded it was too big a step to go immediately to making a totally new rifle. They felt the best approach was to test the concept of having a bullpup butt design as this was revolutionary at that time. (Of interest, just after the WWII, the British had developed a bullpup rifle called the

EM2. It was a rifle that was well ahead of its time.) To do this they would build

a working mockup using L1A1 parts. I visited the SAF Lithgow in late July to meet with the team that was fashioning RMC No2. They too were a great bunch of practical, "can-do" craftsmen with a sense of humour you only

find in a machine-shop full of creative, motivated people. I loved it there. From that effort came

RMC No2.

A Different World. Looking back it was a totally different world in which Australians used to live compared to the one of today with mass shootings in public places, terrorists and suicide bombers. When I was an Army cadet at High School, I used to be allowed to take a .303 rifle home on the train in order that I could shoot at the Redbank Rifle range over the weekend. After I had finished testing the RMC No2 at SAF, it was sent from Lithgow to the Q Store at Duntroon. Shortly after it arrived, I went to the Q Store, signed it out and walked from the Military College at Duntroon around to Army Headquarters. I arrived at G Block, rifle in hand, and spoke to the Commonwealth Policeman on guard, saying I was there to see the Scientific Advisor for the

Army. He rang the Scientific Advisor's PA, she came down, greeted me and took me up to his office. No one blinked or challenged me. After the meeting I walked, with rifle, back to Duntroon. Today it would be totally inconceivable for anyone to walk around with a rifle in public, let alone take one into Army Headquarters in such an informal manner.

Army Design Establishment(ADE) - A Negative View |

ADE Report

of RMC No2 Rifle

28 Apr 1972

(Click to read)

|

RMC No2 was sent to ADE in early 1972 and a report was issued by them on 28th of April. The report, written primarily by a public servant, LtCol Mike Chivers (Retd British Army), was entirely negative; the author being unable to see beyond what was to what could be. It was badly written and riddled with errors of technical fact. A later assessment by the Special Air Service Regiment also confirmed that the author had little understanding of user requirements relating to such things as weapon balance and the ergonomics associated with the immediate actions necessary when there was a weapon stoppage.

I had already met Chivers during one of my visits to ADE. An ex-British officer, with the typical grey nicotine stained moustache, who lacked an engineering degree but had somehow insinuated his way into the business of small arms design and development. During my meeting with him, he thrust forward a book on small arms design that he had compiled over the years and about which he was very proud. It resembled something very much like W.H.B. Smith's, "Small Arms of the World" and I remember being very impressed with the size of it and the effort it must have taken him to compile.

All in all though, I found it disappointing to meet someone who held no tertiary qualifications in engineering, had no imagination and could not see the possibilities this development offered him personally. I went to some length to explain to him that this was a wonderful opportunity, for him, for ADE and for the Small Arms Factory at Lithgow, to do something really interesting and creative. He could take this working mockup and turn it into anything he wanted provided he stuck to the concept of building a rifle with a bull-pup butt that was capable of being operated with equal ease by left and right handed people. Even though the Australian Army had no immediate intention of introducing a new rifle, it made sense to develop the plans for one now and continually refine

those plans. When, finally, a decision was

made to phase out the L1A1, it would be possible to bring out the developed plans and take the rifle immediately into production. He really wasn't interested in this; his desire to jealously keep the business of small arms design all to himself verged on manic. I remember during this discussion of what could be possible, I intimated that I felt the EM2 was a brilliant piece of work but to my surprise he was luke-warm about it, saying it could not be converted from .280" to 7.62mm. About this I remember there was a strong disagreement. I knew for certain that it would be possible to design the weapon to take a different calibre of round, and it would be possible to use a better, simpler locking mechanism. Chivers was annoyed that someone so "ignorant" would

question someone as knowledgeable, as he thought he was, on this point. I had studied a captured AK-47 at the Royal Military College and I was very impressed with the locking mechanism and the overall

simplicity of the design; particularly the trigger mechanism. (This admiration of the AK-47's design remains with me to this day!) I suggested to him that it would be easy to use the same locking mechanism that was used by the AK-47 with the same piston-breechblock and return spring system. The conversation went nowhere.

|

|

Responses to ADE Rpt

28 Aug 1975

(Click to read)

|

Clearly, the Dept of Supply had hit a nerve. I was in my final year at the Royal Military College when I was informed that ADE had found there was no merit in the rifle's further development. At RMC I had come under the administration of LtCol Dick Flint (who was a friend of my future father-in-law, so there was a bit of a personal connection between us that went beyond Staff Cadet & Supervising Officer. LtCol Flint and his wife were guests at my wedding a few days after I graduated from the college in December, 1972.) I remember him consoling me by saying that ADE had a reputation for "NIH", standing for "Not Invented Here".

I was not shown the report and it was only later, when I was serving as a staff officer responsible for the maintenance policies related to Small Arms and Weapons that I found out there was a file on the rifle and that it had been marked, "Not to be shown to Loughrey".

In the course of my work I had dealings with the School of Infantry and it was there that an officer arranged for the file to be sent to him. He then took copies of key documents and sent them to me. I finally found out what had happened.

If you click on the thumbnail images to the left, it will bring up the scans of those documents with typed verbiage next to it both to assist in their reading and also for the benefit of search engines. The top image will show the report which was Chiver's negative assessment of the rifle. The bottom image provides two evaluations; one by the officer that sent me the documents, the other by Mr Peter O'Dwyer, the senior mechanical engineer working in the Department of Supply. Chiver's inability to "imaginate" is clearly evident in these documents and is in stark contrast to the opinions of Peter O'Dwyer and those which were given by the Special Air Service Regiment four years later.

|

RMC and Field Testing of RMC No2

Easy to Carry. During all of the field exercises at RMC I was allowed to carry RMC No2 and found that, despite being heavier than the L1A1, it was actually a lot easier to carry because the centre of gravity of the weapon was closer to the body. I also fired many, many rounds from the weapon (greater than 5,000. Of interest, the whole of the 2 year engineering class fired 20 rounds each out of the weapon when visiting SAF Lithgow in 1971.). It never suffered a stoppage. The weapon was so well balanced about the pistol grip and so stable to hold that a good friend of mine, Warwick Elliott, used the rifle one handed, like some oversized pistol, to reliably hit a man-sized target in the chest at a range of around 100 metres.

Issues relating to Accuracy. The RMC No2 had the capacity to be extraodrinarily accurate because it was possible to hold it in the prone position, as depicted in Figures 7 and 8, with the non-trigger hand cupping the pistol grip and resting on the ground. The over-reach, where the distance from the shoulder to the pistol grip is longer than normal, is actually an advantage in this posture, causing the firer to be more stable. The centre of gravity of the weapon is just behind the wrist so no effort is required to hold the weapon at a particular angle to the horizontal. It effectively balances on the pistol grip. Besides being extremely accurate, this posture also had the advantage of the firer having a lower profile to the earth; thereby presenting

a smaller target. The weapon's accuracy was an interesting "study". When lying in a conventional prone-unsupported position, the RMC No2 did not group as tightly as an L1A1, albeit, the point of aim was more consistent after the weapon had been used on, say, an obstacle course; the change in point of aim in the case of the L1A1 being caused by its having a flexible hinge between the foresight and the rear sight. Once the L1A1 was flexed as a result of the user being involved in stenuous physical activity, the point of aim would change markedly and re-zeroing was necessary. The RMC No2 was shorter and this shortness actually had a disadvantage in that small movements caused by heart-beat, or nevous twitching, cause significant changes in angularity of the axis of the

barrel compared to a longer weapon. The longer weapon, with its centre of gravity being between the shoulder and the forestock, and in front of the pistol grip, also offers greater inertia to any movement and so is steadier in the typical prone unsupported position. A similar phenomenom is noticed when using the Steyr or SA-80, or, I suspect, any other bull-pup butt weapon where the end result is far shorter than a conventional rifle. The advantage, though, of a bull-pup weapon lies in the ability to adopt what is now called the basic prone position. In that position, the RMC No2 consistently produced a much tighter group than was possible with the L1A1, even when the latter was fitted with a sling.

Trigger Linkage better than Expected. The trigger mechanism on the RMC No2 was makeshift (and deliberately so as the objective was to quickly build a working mock-up to test the overall concept.) Although the trigger linkage was exposed, amazingly it was never damaged and never gave trouble. Obviously, in a future more refined prototype, this would all be integrated into the receiver of the weapon. It would be useful to examine how all of the modern bull-pup butt weapons have addressed the issue of trigger linkage; particularly the EM-2.

High Foresight, surprisingly, not a Problem. I was equally surprised by the high foresight. I thought it would catch on things. My preference was to eventually have an optical sight like the EM2. I couldn't see how this could be expensive as I owned a number of rifles with telescopic sights at home. The high foresight never once became entangled in brush. After a while, I used to use the foresight like an instrument to move aside thorny vines when I was patrolling.

Nothing Beats Physical Testing. The lesson to be learnt from this is that nothing can substitute for actually physically (and personally) trying out something to really see if it is a problem or whether it is simply imagined. The ADE report is an excellent example of how people will see problems that are not there or make out that problems that can be remedied by good design or lateral thinking are insurmountable.

Jungle Training Centre. At the end of 1972, I graduated from Royal Military College with an honours degree in Mechanical Engineering. After graduation, all graduate engineers had to attend a 4 month course at Jungle Training Centre, Canungra. RMC No2 followed me there. I showed it off to the directing staff and demonstrated its accuracy on the Cunungra range. The rifle was capable of hitting a 1 gallon (4.5 litre) can of paint at 600 metres with the scope fitted. With aperature sights, it could consistently put a round up the centre of a 38mm diameter "whiz-bang" training aid, at 100 metres, causing it to detonate. Everyone who saw the rifle was excited by its possibilities and impressed with its performance. The prediction by

ADE, in paragraph 9 sub-paragraphs(c) and (d), that the joint piston breechblock slide arrangement would result in unsafe, unreliable operation and failure proved to be entirely wrong. In all the rifle fired many thousands of rounds and never once had a stoppage or suffered a failure.

3 Base Workshop Battalion

LtCol Faulks letter

to 3 EME Gp

28 June 1973

Colonel Allen-

Seeking AHQ Approval to

develop RMC No2 further

18 July 1973.

|

I was posted to 3 Base Wksp Bn as the OC of an Automotive Engineering Company. The rifle followed me there. I was fortunate to have as my first CO, LtCol John Faulks. John Faulks went on to become the Director General of Electrical and Mechanical Engineering. Later, I had the opportunity to work with him again when I was posted to the Directorate as the SO2 EME Systems Development. LtCol Faulks was supportive of the further development of the rifle and so he wrote a letter to the Colonel EME at HQ 3 EME Gp, a part of the HQ 3 Military District, seeking approval for "minor improvements" to be done to this rifle.

In actuality, the further work went well beyond minor improvements. Once again, cannibalised parts from an L1A1 were used to make the weapon. Working at 3 Base was not without its rough times. Soon after I had arrived at 3 Base Wksp, LtCol Faulks was replaced by LtCol Kenneth Rawnsley. From the beginning I found Rawnsley to be difficult. I was initially in charge of Automotive Engineering Company and had effected many improvements there ranging from the way parts were ordered to the way caustic baths were heated and engines were tested. The rifle was being made in General Engineering Company so I asked if it would be possible for me to be transferred to be OC of that Company. I was also sports officer, the person responsible for

the coordination of the RAEME birthday celebrations, including the atheletics carnival (where, incidentally all the beer was stolen!!), the rugby officer and held a mess appointment and so I asked that I be allowed to concentrate more on my weapons development than my extra-regimental appointments. Soon after making that request I was sent away to a course at RAEME Training Centre and I received a strong letter from Rawnsley which I found to be bizarre. When I returned to 3 Base Wksp after the course and confronted him about it, it was as if nothing had happened! I went back to work.

When the Head of Army Design Establishment learnt of this development, he pressed the Director of RAEME, Brig J.C. Dean, to cease all work, saying that RAEME had far exceeded its authority, broken countless regulations and gone way beyond its charter by undertaking such a development.– As I've mentioned, ADE, from the outset, driven by an Ex-British officer, LTCOL Michael Chivers, had been very negative regarding these ideas. I can't remember how I learnt that a Warrant Officer called Stan Whitwell had been despatched from Army Headquarters at Albert Park to destroy the rifle and all plans and correspondence relating to it but, hearing he was on his way, I rushed over to the Q Store to ask the QM, Captain Mike Stark, a friend of mine, to bring

the rifle to charge on the Workshop's weapon's register. Once brought to charge, the rifle could no longer be destroyed without a certificate of destruction being raised and this would have brought it very much to the attention of a number of authorities outside of RAEME. As a consequence, Whitwell refused to be involved in the weapon's destruction and so I discretely continued to work on it until it was at a state where it could be sent to the Infantry Centre museum, Singleton. It remains to this day on display. (Of interest, I later came to work with Stan Whitwell as my Warrant Officer Class 1 when I was in charge of weapons maintenance policy. He was a terrific person and so was his friend WO1 Ian Cummings.) By the time the

rifle was sent to Singleton, I had fired quite a large number of rounds from it. Being much lighter (about 8.4 lbs fully loaded) than either the RMC No2 or a normal L1A1 (11lbs 15oz fully loaded), the KAL 1 had quite a sharp recoil, verging on painful. If I had been able to work on it further, I would have looked at the possibility of having an extensible butt with a shoulder pad or built in damper that absorbed the recoil better than the solid butt the weapon presently has.

|

Making the Rifle suitable for Left-handed Firers or...A Lesson in finding Simple Solutions

The matter of making the rifle suitable for both right and left handed firers has always been prominent in my mind. And that, of course gets the mind thinking of all the ways of making this possible. Safety catch, cocking handle, sight adjustment knobs on both sides, are relatively straight-forward; the one that is the most difficult relates to cartridge case ejection near the face of a left-handed firer. It's often amusing to me, especially when I was younger, how I would run off into the most esoteric solutions when there was a simple one staring me in the face (in this case literally!!).

Cartridge Case Ejection and the Adjustable Stationary Ejector. (almost a contradiction in terms!)

For example, one solution I was toying with was to adapt the existing stationary ejector so that it could be moved and sit on either the left or right hand side of the rifle's body to effect ejection to the right or left respectively. The stationary ejector of the L1A1 sat on the left hand side of the rifle's body and so knocked the case out to the right and forwards through the ejection port. A possible problem with an adjustable stationary ejector was what would happen if the firer did not actually position it properly so that it sat somewhere between the left and right. One possibility of avoiding that happening would be to have a mechanical arrangement that prevented the weapon from firing unless ejector was firmly and correctly positioned. As with most

things mechanical, this then brings another problem and that is, "How would the firer know that the weapon was not going to fire if they had accidentally not put the ejector in the correct position?". Could this cause the firer to lose precious seconds and possibly his/her life in the process?

To get around that possibility, I thought that it would be necessary to arrange things such that the firer had to "over-cock" the weapon in order to move the stationary ejector. When the working parts slid forward into their normal operating position, the ejector would be held in position by the presence of the bolt. The rifle would have to have two ejector port openings, one on the left and one on the right, but like the M16A1 they would have a spring-loaded flap such that the one that wasn't being used would remain closed to dirt and debris.

Looking at Figure 7, the answer to achieving left and right handed firing actually seems quite simple. It can be seen that the firer has their right eye closed and is well over the top of the weapon. The ejection port is well forward of the face. Imagine if the ejection port opening was extended and curved down in its final stages a little like the pinna (or auricle) of an ear. The face would be protected from any debris being blown out of the breech and the round could not come back into the firer's face. Additionally, when the weapon was being fired from the hip, the extended lip on the ejection port would ensure there was clearance between the body of the firer and the rifle to allow cases to fall to the ground. I did carry out tests firing

the weapon left-handed at the hip and found the ejection cases sometimes hit my basic pouches but, because of my webbing, caused me no discomfort whatsoever. Nowadays we wear body-armour and so it is even less of a problem.

|

Assessment by Special Air Service Regiment

Submission to

assess Rifles

Assessment

of RMC No2

|

Before graduating from the Royal Military College, I toyed with the idea of going into Infantry on graduation and even went over to the Directorate of Infantry at Russell Offices, as a cadet, to have discussions with Major Peter Leeson; an officer who held a Science Degree and was happy to discuss with me the possibilities of joining Infantry. When the Vietnam War came to a close, Infantry lost its allure to some extent and, besides which, as the only graduating Mechanical Engineer of that year (and the first cadet to ever graduate from the RMC with a Mechanical Engineering Degree!), I was told there was no way Brigadier J.C Dean, then the Director General of RAEME, was going to let me go to another Corps. The idea of gaining some experience (and adventure!) in infantry did not leave me and so, in 1975, I applied to undertake the Special Air Service Regiment selection course with a friend of mine and fellow RAEME officer, Capt John Trevivian. John had graduated one year ahead of me at RMC Duntroon. It was possible in those days to serve two years and then return to RAEME. When Brig Dean found out about this, he made it very clear we would not have a career if we went on the course. John Trevivian disobeyed his direction and, sure enough, from that time onward, his career was stunted. For that and other personal reasons (my wife had just become pregnant with our first child, Felicity) I decided not to press the matter.

Another friend of mine and classmate from RMC Duntroon, Capt Patrick Cullinan asked me if I would talk to his troop about the rifle. (Patrick is a truly exceptional person. Read the book "White Sherpas". Patrick was the first Australian Military member to climb Mt Everest. His team were the first and only team to ever do this without Sherpa support. Patrick and his climbing partner, Paul Bayne, survived for 6 days in the "death zone" before then going on to conquer the summit. A previous team of Japanese climbers had perished after 4 days in the zone!) So I travelled to Watsonia Army Barracks where they were staying and delivered a presentation. This talk generated a lot of interest so, as a result of that response, Pat arranged for the two rifles, RMC No2 and KAL1, to be sent from the Infantry Centre to SASR at Swanborne in Western Australia for further evaluation. In Pat's submission there is a little confusion in that he has mistakenly thought that RMC No2 was KAL1 and (sensibly) the KAL1, being the second working model, was KAL2. SASR was informed that the second weapon was in no state to be fired and so it was left out of the assessment. It had been fired in 1974

at 3 Base Wksp, but by the time it had reached the Infantry Centre it looked as though it had suffered some damage. There was black insulation tape holding the foregrip in place and it looked pretty much the worse for wear.

I was not involved in the trial and not consulted in any way and I think that was a good, rather than bad thing, as it ensured I couldn't in any way bring pressure to bear on the assessors. The results of this assessment were fair and I found the level of imagination SASR exercised to be refreshing compared to Army Design Establishment.

I was surprised to hear that the weapon had not performed as well, in terms of its accuracy, as the L1A1 for that had not been the case in the past tests. On reflection, it is almost likely the comparison was performed with both rifles being fired from the prone unsupported position. As explained above all bull-pup weapons, being significantly shorter, do not perform as well as long weapons in the prone unsupported position. But, in the case of the bull-pup configuration, it is possible to have another position, where artificial aids, such as slings, sandbags or the like, are not employed, which is not practical for a conventional rifle. This postion is the "basic" prone position (as it has now come to be called with the Steyr) where the non-trigger hand is

cupped under the pistol grip. In that position, at Jungle Training Centre, Cunungra, I was able to regularly achieve 2 inch groups at 100 metres. In 2011, I shot at the Australian Army's Skill at Arms Meeting with the Steyr and found with this weapon, the same improvement to accuracy when using the "basic prone" position applies.

The SASR Report recommended the rifles be sent back to ADE for further consideration. As to be expected, nothing ever came of that.

|

|

Concluding Thoughts

These rifles bear a strong similarity to the present Steyr Rifle with which the ADF is now equipped. It was introduced into service in 1985, 14 years after RMC No2 Rifle was made at Lithgow. The KAL rifles, in concept, are significanly superior to the Steyr in a number of ways:

|

-

The KAL1 is designed to be fired with equal ease by left and right handed people whereas the Steyr is really only suitable for right-handed people.

-

The KAL1 demonstrated how it was possible to have a rifle that field stripped into only three major components and so was very easy to maintain in the field. By comparison, the Steyr strips into 12 parts, some of them very small and easily lost in the humus of a rain-forest floor. Reassembling the Steyr's bolt, especially if frightened, tired and/or nervous is really testing. The Steyr employs two springs to effect the return of working parts. This arrangement is sealed in two tubes and requires an armourer to replace them. There have been a number of problems with this arrangement. The AK-47 with its combined return spring and piston spring doesn't appear to have any problems, even in the dirtiest of conditions.

-

The rifle uses a stationary ejector, a similar system of which is used in the AK-47, is simple and reliably knocks the spent firing case forward of the firer.

-

A frequent cause of unexpected malfunction with the Steyr is the caused by the user not properly seating home the magazine. This can happen even with experienced shooters when rushed. Additionally, the means of magazine release requires the user press upwards with their thumb. This is an unnatural movement, not conducive to magazine extraction and uses one of the weakest movements of the thumb; particularly if the thumb has been damaged or is weak from extreme cold. Conversely, the thumb is very strong when used in a gripping action as is the case with the AK-47 and the L1A1.

-

The Safety catch in front of the trigger is significantly better than the Steyr's left to right sliding catch and allows ease of operation by left and right handed operators. When people are frightened, they cannot easily tell left from right. With the Steyr, it is easy to forget which position turns the safety catch off. With the KAL rifle, firers cannot put their finger on the trigger with the safety catch on. This means if they are surprised, they will not inadvertently try to fire the weapon with the safety catch on. There have been a number of recorded incidents where policemen lost their lives because, in fright, they lost precious seconds trying to use their weapon with the safety catch on!

-

The Steyr has no trigger guard, most probably to facilitate the use of mittens (something Australian soldiers rarely use). It is easy when picking up the weapon to accidentally turn off the safety catch with the palm of the hand and, at the same time, have a finger slide up onto the trigger setting off the weapon. So bad is this feature, that the Australian Army now teaches its troops to pick up the weapon at the point between the pistol grip and the magazine. This breaks a "sacred" basic Infantry teaching, that you must always hold a weapon by its pistol grip so that you are always ready to use it.

-

The gas escape port is located such that it is easy for a firer to accidentally place the forefinger of their forward supporting hand over this port. The force of this gas is that, even with gloves on, it is possible to dislocate the joint of the finger in extreme cases.

-

The muzzle blast, though substantially less than that of the L1A1, is still deafening and upsetting to people lying next to the firer. Some form of noise attentuation device is required on all high powered small arms; not just the Steyr.

I still remain convinced that a bull-pup butt rifle offers the best design to the military for a general purpose weapon that sits somewhere between a sub-machine gun and a sniper's rifle. My life is always overly-full with projects of various natures but this is one project I would really like to finish off, to see a final polished production-ready model. I have already, at the beginning of this page provided what I believe is necessary to have a weapon that satisfies the needs of the military. If I were to start now, I think I would look for a weapon that was already largely headed in the direction I wish to travel. As an example, one such weapon, the Dragunov SVU-A, can be found at this website.

The Dragunov SVU-A is, interestingly, a bull-pup butt sniper rifle with an AK-47 locking action, capable of automatic fire, with noise suppressor (very similar to the one I developed in 1972 for my engineering thesis) and recoil-brake. Another weapon that would be an interesting study and possible starting point for a development would be the Chinese QBZ-95. Both use a bolt action similar to the AK-47 and, by way of showing how it is possible to calibre a weapon to whatever size you might wish, one is 7.62mm, the other is 5.56mm. As for me, I think if there were no compelling reasons to stick to existing calibres, the best calibre for infantry

use, when all things are considered, is around 6.25mm, a 110 grain projectile, with a muzzle velocity of around 1,000 metres/sec. The area in small arms ammunition design that most attracts my interest is how to reduce the size of the cartridge case (caseless ammunition notwithstanding!) and still be able to achieve the muzzel velocities I seek for an acceptably flat trajectory out to 500 metres. If you have an interest in this sort of thing, the best site (including the fact it is superbly written) I have ever found on this subject is by Anthony G Williams, "ASSAULT RIFLES AND THEIR AMMUNITION: HISTORY AND PROSPECTS (Revised 2 April 2011)". On that site there is a picture of Anthony firing an EM-2 which

fills me with envy!

KEVIN LOUGHREY

8 SEPTEMBER 2011

|

Fig 9.

Recent 7.62mm Russian Bull-Pup Butt Sniper Rifle

with Noise Suppressor and Automatic Fire Capability

Fig 10. Chinese 5.56mm Bull-Pup Assault Rifle

with AK-47-like bolt and locking system.

|